Our Services

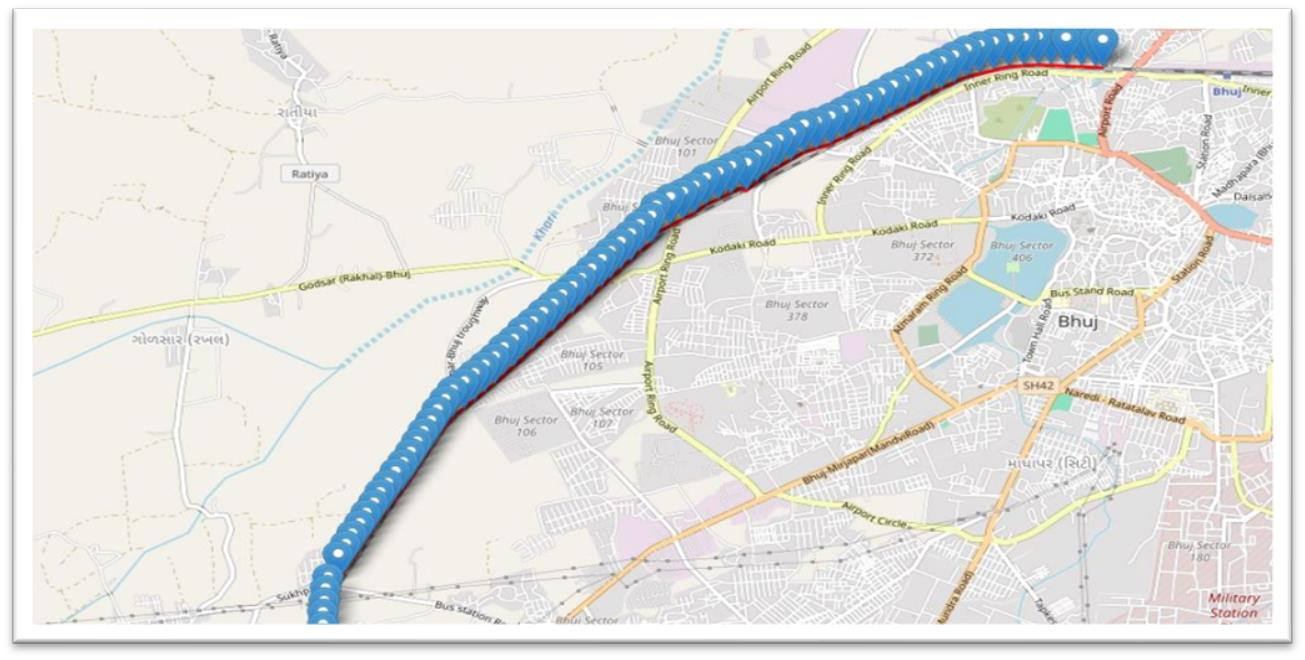

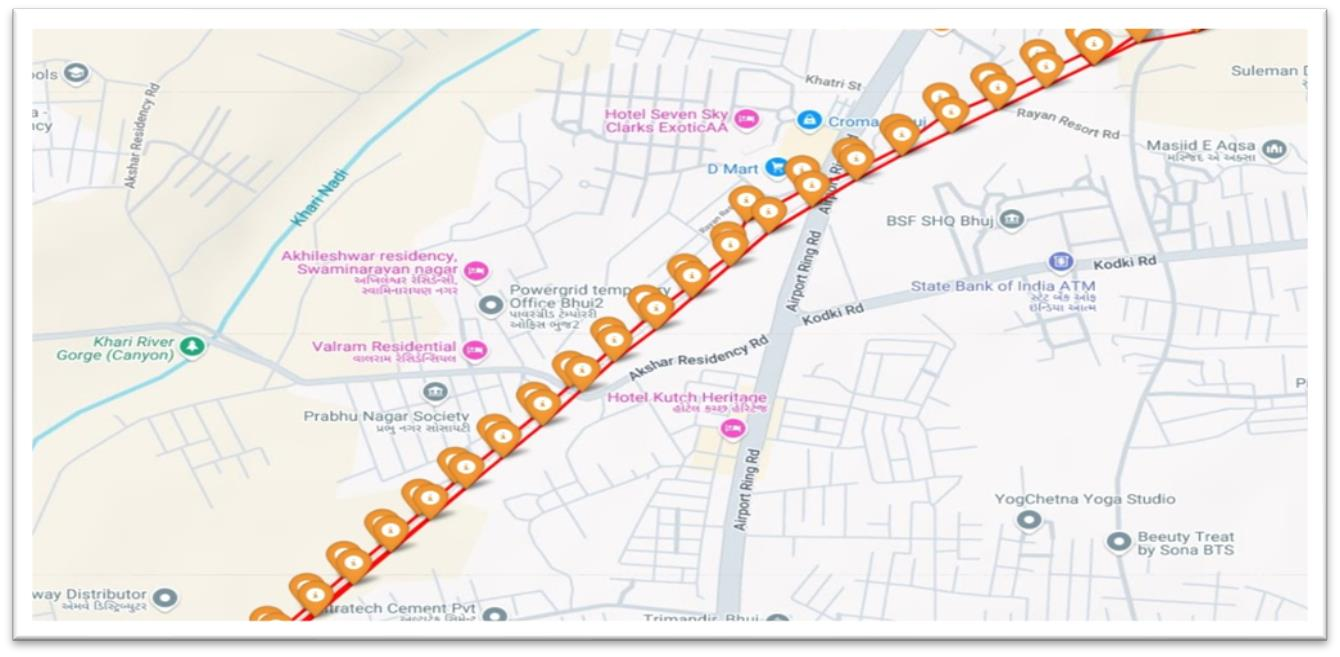

MULTIFUNCTION CABLE LOCATOR WITH GEO TAGGING

About

Our engineering design services combine technical expertise with innovative solutions to deliver high-quality drawings and specifications that meet your project requirements.

Our cable tracing and geo-tagging tools ensure precision in underground cable management, reducing errors during construction.

ISSUES IN UG CABLE MANAGEMENT

- Difficulty in identifying the exact path of buried cables.

- Identifying the specific cable among multiple underground lines during maintenance.

- Keeping track of cables manually is prone to errors and inconsistencies.

- Cables are often damaged by external activities like digging and construction.

Our Solutions fix these

- Comprehensive Database creates a digital map of all underground cables, providing a central record.

- Real-Time Tracking: The database can be accessed anytime, allowing for easy location tracking and network updates.

- Enhanced Planning: Geo-tagging helps with network expansion, maintenance planning, and construction projects.

3D VIRTUAL TOUR

WHAT IS 3D VIRTUAL TOUR?

- It is a comprehensive spatial data platform that captures, processes, and delivers 3D models and virtual experiences of physical spaces.

- It uses a specialized 3D camera and proprietary software to create highly accurate and interactive digital twins of any environment.

- Applicable to various settings, including residential homes, commercial properties, construction sites, and beyond.

-

Experience immersive 3D walk-through virtual tours for facility audits, training, and spatial planning.

Key Features

Immersive 3D Experiences: The 3D models allow users to virtually walk through and explore spaces in rich detail, providing an unparalleled level of engagement and understanding.

Precise Measurement Tools: The platform's advanced measurement capabilities enable users to accurately document and analyze the physical dimensions of any environment.

Seamless Collaboration: The cloud-based platform facilitates real-time collaboration, allowing multiple users to access and interact with 3D models simultaneously.

Solutions and Benefits

Problem 1: Regulatory Audits / Remote View

Solution: 3D Virtual Tour

Benefit:

- Allows auditors and guests to view specific areas remotely from their desktop or conference room.

- Facilitates a first-view experience of the facility without requiring physical presence.

Problem 2: Investigation in Aseptic Areas

Solution: 360-Degree Digital Twin

Benefit:

- Enables the investigation team to examine and understand potential issues without entering restricted areas.

Problem 3: On-Job Training and Evaluation

Solution: Matterport Digital Twin integrated with VR Tools

Benefit:

- Offers new employees an immersive experience to simulate working with critical machines and performing complex tasks.

- Provides intricate details, including actual depth, accurate measurements, spatial data, and zoom capabilities.

Result:

- Effective training without needing access to critical areas.

- Ensures better preparation and understanding for trainees.

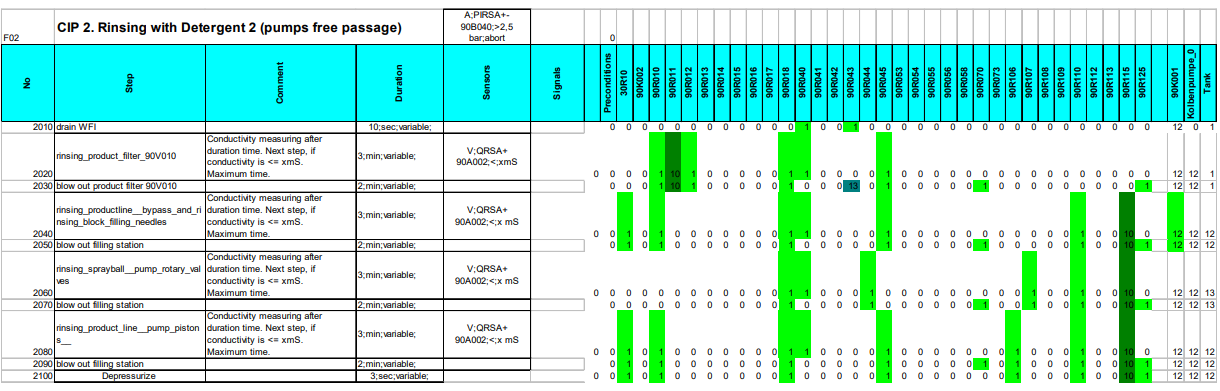

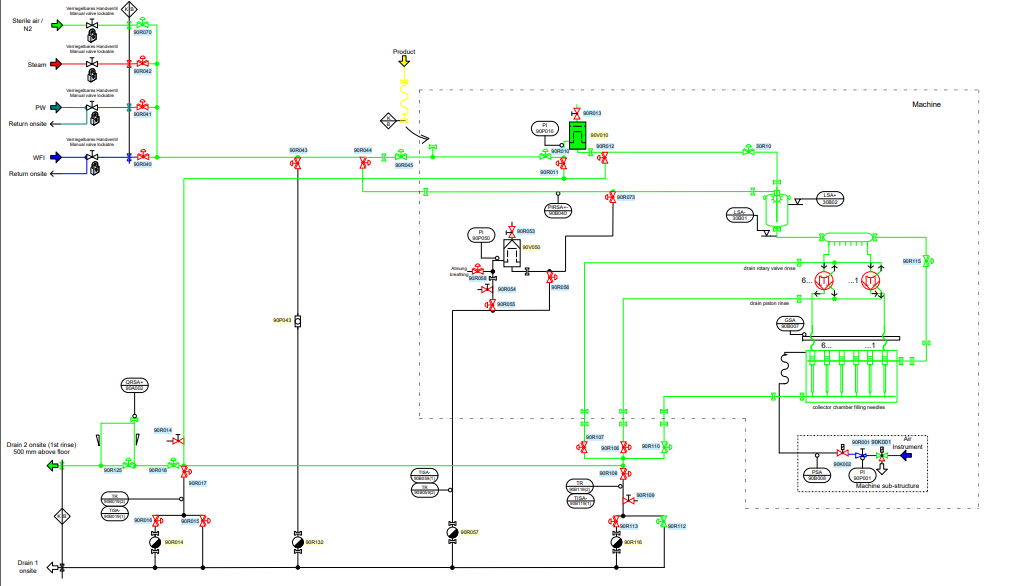

PROCESS FLOW DIAGRAM

Engineering made easier to understand

About

Our process flow diagram services provide detailed visual representations of industrial processes, helping to document and optimize workflows, identify potential improvements, and ensure regulatory compliance. We create clear, standardized diagrams that map out the sequence of operations, equipment connections, and process control points.

The SOLUTION WE PROVIDE

The Process Flow diagram solutions we provide will have the

following information but not limited to:

The exact flow of steam/WFI during sterilization/cleaning,

with exact status of each valve and the sequence in which they

are opened and then closed. All incremental stages of

sterilization/cleaning will be clearly indicated on the

drawing.

The condition of the valves after completion of SIP, which

will ensure integrity of the system will be clearly indicated

using the drawing.

The exact flow path of the product, which is already covered

by the sterilization can be indicated on the drawing.

Each and every instrument and mechanical components such as

valves with their actual tags as built will be shown on the

diagram with their relevant details, parameters and its

operational limits. This will help in easier understanding and

troubleshooting.

Examples

Examples